Carbon steel, as one of the the most widely used and cost-effective engineering materials, serves nearly all industrial sectors – including construction, machinery, automotive, shipbuilding, and energy – in various forms. Among these, plate/sheet, pipe/tube, bar, and strip constitute the core shapes of carbon steel products. Below is a detailed analysis of the characteristics, processes, standards, and applications of these four major categories of common carbon steel products.

I. Carbon Steel Plate/Sheet

Plate/sheet refers to flat-rolled products with relatively small thickness compared to width and length. Conventionally classified by thickness:

Hot Rolled Carbon Steel Plate/Coil

Medium/Heavy Plate: Large structural components (bridges, building steel structures, ships, pressure vessels, storage tank bases, construction machinery frames, wind turbine towers, large mold bases, etc.).

Hot Rolled Sheet/Coil: Automotive frames, wheels, chassis rails, agricultural machinery structures, various ducts, raw material for structural tubes (e.g., square/rectangular tubes), auxiliary building structures, simple stamped parts (where high precision and surface finish are not critical).

Medium/Heavy Plate : Thickness usually ≥ 4.5mm (some standards start from 3mm), width can exceed 3 meters, lengths can reach over ten meters. Representative grades: Q235B, Q345B (GB), SS400, SM490 (JIS), A36, A572 (ASTM).

Hot Rolled Sheet/Coil : Thickness < 4.5mm (typical range 1.2mm - 20mm), often supplied in coil form. Representative grades: SPHC (JIS - General structural), Q235A (GB), 1008, 1010 (ASTM SAE).

Process: Steel slabs are rolled at high temperatures (typically above the recrystallization temperature) through multiple passes.

Thickness Range:

Surface: Typically has a blue-gray mill scale (iron oxide formed at high temperature), relatively rough surface.

Properties: Moderate strength, good plasticity and toughness, excellent formability and weldability.

Cold Rolled Carbon Steel Sheet/Coil

Process: Using hot rolled coil as raw material, rolled at room temperature (cold deformation).

Thickness Range: Typically very thin, commonly 0.3mm - 3.0mm, mainly supplied in coil form.

Surface: Smooth, clean, free of scale, high dimensional accuracy (tight thickness tolerance), flat profile.

Properties: Significantly higher strength and hardness compared to hot rolled sheet of the same grade, slightly lower plasticity and toughness. Excellent press formability (especially deep drawability), bending performance, and surface finish quality.

Representative Grades: SPCC (JIS - General use), DC01 (EN - Cold forming), 1008, 1010 (ASTM SAE), St12 (DIN).

Main Applications: Applications requiring high precision, good surface, and excellent formability: Automotive body panels (doors, hoods), appliance casings (refrigerators, washing machine panels), office furniture, filing cabinets, computer cases, building interiors, kitchenware, hardware parts, substrate for coating (galvanizing, painting, etc.).

Galvanized Carbon Steel Sheet/Coil

Hot-Dip Galvanized : Most common, thicker zinc coating (e.g., Z03: 30g/m² per side, Z12: 120g/m² per side - JIS G 3302), excellent corrosion resistance, surface has spangle pattern (controllable). Grades: SGCC (JIS - Hot-dip galvanized), DX51D+Z/AZ (EN).

Electro-Galvanized : Thinner, more uniform zinc coating, smoother and more aesthetic surface, corrosion resistance inferior to hot-dip, better weldability, higher cost. Grades: SECC (JIS - Electro-galvanized), DX51D+ZE/AZE (EN).

Process: Continuous immersion coating (hot-dip galvanizing) or electroplating (electro-galvanizing) of a zinc layer onto cold rolled (common) or hot rolled (less common) sheet.

Main Types:

Main Applications: Applications requiring corrosion resistance: Roofing, siding (substrate for paint coating), ductwork, automotive inner/outer panels (body panels, underbody parts), air conditioner casings, appliance housings, agricultural equipment, grain silos, guardrails, containers, etc.

II. Carbon Steel Pipe/Tube

Pipe/tube refers to long products with a hollow cross-section. Broadly, "Pipe" often implies conveyance piping (focus on pressure containment, flow capacity), while "Tube" often refers to structural/mechanical tubing (focus on dimensional accuracy, mechanical properties), but the distinction is not absolute.

Seamless Carbon Steel Pipe/Tube

Structural Seamless Pipe/Tube : GB/T 8162 (common grades Q235B, 20#), ASTM A53/A106 (for fluid conveyance but often used structurally), EN 10210-1 S235JRH, etc. Used for engineering structure supports, bearing sleeves, machine parts.

Fluid Conveyance Seamless Pipe : GB/T 8163 (common grades 20#, 16Mn), ASTM A106/A53 (high-pressure/high-temperature steam, water, oil), API 5L (oil & gas transmission). Used in boilers, heat exchangers, chemical piping, oil/gas pipelines.

Precision Mechanical Seamless Pipe/Tube : GB/T 3639 (Cold-drawn/rolled precision tube), ASTM A519 (for mechanical drive shafts). Used for hydraulic cylinder barrels, piston rods, precision instrument components.

Process: Solid steel billet is pierced, rolled, drawn, etc., to form a tube wall that is continuous without a welded seam.

Properties: Excellent overall uniformity, strong pressure-bearing capability (especially high pressure/temperature), superior fatigue resistance.

Main Types & Standards:

Main Applications: High-pressure piping (oil, gas, water, steam), boiler tubes, heat exchanger tubes, mechanical structural fittings, high-strength drive shafts, bearing housings – critical pressure-bearing or load-bearing components.

Welded Carbon Steel Pipe/Tube

Low-pressure fluid conveyance (non-corrosive media: water, gas, oil).

Building steel structures (columns, beams, trusses).

Structural supports, equipment frames/casings.

Protective structures (guardrails, fencing, scaffolding).

Agricultural equipment, HVAC systems.

ERW Pipe/Tube : Most common, good dimensional accuracy. Grades: Q235B (GB/T 3091 - Low-pressure fluid conveyance welded pipe), SPHT1/2/3 (JIS G 3444 - Structural tube), ASTM A53 F (galvanized or black).

SSAW Pipe : Suitable for large diameters (>Φ406mm), commonly used for long-distance, low-pressure fluid conveyance (water, gas).

LSAW Pipe : For medium/large diameter thick-wall pipes, high strength, used in critical applications (e.g., oil/gas trunk lines - API 5L X52/X60/X65/X70/X80, etc.).

Square/Rectangular Hollow Section - SHS/RHS : Primarily made by forming strip steel into a round tube via ERW and then cold forming into square/rectangle, or directly roll-formed. Grades: Q235B (GB/T 6728), ASTM A500 Gr B/C. Used for building and structural frames, supports, guardrails.

Galvanized Steel Pipe : Welded pipe hot-dip galvanized. Grades: Q235A/B (GB/T 3091), ASTM A53 F (Galvanized). Used for low-pressure water/gas lines, building conduit, scaffolding, guardrails.

Process: Carbon steel strip/sheet is formed into shape (longitudinal seam) or spiral shape (spiral seam), then welded (ERW - Electric Resistance Welding, LSAW - Longitudinal Submerged Arc Welding, SSAW - Spiral Submerged Arc Welding).

Characteristics: High production efficiency, low cost, wide size range (especially large diameter thin wall). The weld seam is a potential weak point.

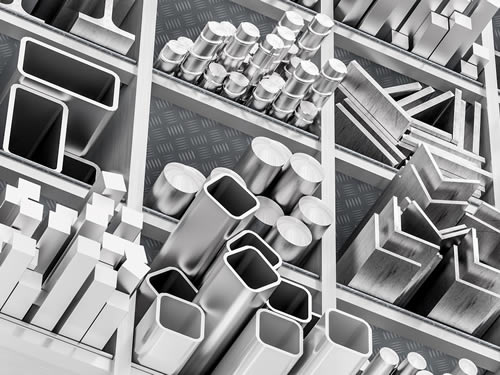

III. Carbon Steel Bar

Bar refers to long solid products with various cross-sectional shapes:

Round Bar

Process: Hot rolling, hot forging (open die/closed die), cold drawing (precise finish).

Size: Wide diameter range: from a few mm to several hundred mm.

Grades: Q235B, 45# (GB), S45C (JIS), 1045 (ASTM AISI), C45 (DIN EN). Can be selected based on requirement: forging stock, structural steel, engineering steel.

Applications: Machine parts (shafts, pins, bolts, bushings, connecting rod blanks), building anchors, fasteners, mold accessories, tool blanks, structural components.

Square Bar

Process: Primarily hot rolled.

Size: Side dimensions (e.g., 10mm - 150mm).

Grades: Q235B (GB/T 702), S20C/S45C (JIS), 1018/1045 (ASTM).

Applications: Tool handles, frame parts, machine tool guides, hardware fittings, auxiliary building structures.

Flat Bar

Process: Hot rolled.

Size: Width (10mm - 300mm) > Thickness (3mm - 60mm).

Grades: Q235B (GB/T 704), SS400 (JIS).

Applications: Straps, blades, grating, welding rods, structural gusset plates, knife blanks, guide shims.

Hexagon Bar

Process: Hot rolled, cold drawn (precise finish).

Size: Across flats dimensions (e.g., 6mm - 80mm).

Grades: Q235B (GB/T 705), SCM440 (alloy steel JIS), 12L14 (free machining steel).

Applications: Bolt and nut blanks, various wrenches, socket heads, machine adjustment shims, tool accessories.

Others: Angles, channels, I-beams, H-beams belong to more complex Sections, which, while broadly similar to bar, are conventionally categorized separately.

IV. Carbon Steel Strip

Strip is a thin, rolled flat product with a large width-to-thickness ratio, typically supplied in coil form (strip coil).

Hot Rolled Carbon Steel Strip/Coil

Process: Steel slabs hot rolled into thin strips and coiled.

Size: Thickness usually <6mm (common range 1.2mm - 8mm), width can be narrow or wide (tens of mm to over two meters).

Characteristics: High production efficiency, low cost, mill scale surface, larger thickness tolerance than cold rolled.

Grades: SPHC (JIS - General), Q235A/B (GB), 1006/1008 (ASTM).

Applications:Raw material for welded pipe (square/rectangular tube, round pipe) - most important use; raw material for cold rolled strip; narrow strip for cold-formed sections, structural parts, stamped components (where requirements are not strict); backsaw blade material, etc.

Cold Rolled Carbon Steel Strip/Coil

Process: Hot rolled coil pickled and cold rolled before coiling.

Size: Thinner (typically 0.1mm - 3.0mm), width adjustable.

Characteristics: High dimensional accuracy, smooth surface, good flatness, high strength/hardness.

Grades: SPCC (JIS), DC01/DC04 (EN).

Applications: Precision stamped parts, hardware components, architectural trim (e.g., baseboard), packaging materials (requires further treatment), substrate for downstream processing such as galvanizing, painting, laminating (crucial use); tube making (high-precision welded tubes demanding dimensional accuracy/surface quality).

Summary & Material Selection Guidelines

Plate/Sheet: Used for large-area covering, structures, container fabrication. Hot rolled focuses on structural strength, cold rolled on precision forming, galvanized on corrosion protection.

Pipe/Tube: Used for conveying media or building frame structures. Seamless for high-pressure/high-temperature precision applications; Welded pipe (especially SHS/RHS and galvanized) for structures, low-pressure fluid conveyance - large volume & wide application.

Bar: Used for manufacturing parts or as structural elements. Round bar is the most versatile; flat, square, and hex bars meet specific shape requirements.

Strip (Coil): Represents the narrow-width form and specific application extension of plate/coil, with continuous processing capability as its core value. Hot rolled strip is the core raw material for welded pipe; cold rolled strip is key for high-precision stamped parts and coated substrates (galvanized/painted).

In practical engineering material selection, comprehensive consideration is needed:

Functional Requirements: Mechanical properties: strength, stiffness, toughness, fatigue strength, wear resistance, etc.

Service Environment: Corrosivity (air, liquid media), temperature/pressure, wear. Determines need for coatings or special treatments.

Manufacturing Processes: Forming method (stamping, bending, drawing), welding requirements, machining requirements. Influences demands on plasticity, weldability, hardness, etc.

Cost Control: Material cost, processing cost, maintenance cost (e.g., galvanized pipe has lower maintenance than black pipe).

Aesthetic Requirements: Impact of surface condition on the final product appearance (e.g., cold rolled sheet, electro-galvanized sheet, precision finished bar).

Familiarity with the characteristics and applicable ranges of various carbon steel products is key to selecting the optimal cost-performance material combination in complex engineering design and manufacturing. Carbon steel, with its powerful adaptability and economy, will continue to play an indispensable role in the industrial sector.