Below is a detailed classification of stainless steel based on processing methods, cross-sectional shapes, material grades, application scenarios, and other key dimensions for quick understanding and selection:

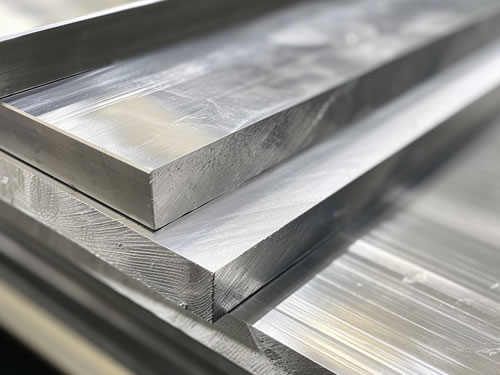

I. Classification by Processing Technology

| Type | Processing Method | Characteristics | Typical Products |

|---|

| Cold-rolled Profiles | Cold rolling (rolled at room temperature) | Smooth surface, high dimensional accuracy, strong mechanical properties (e.g., high hardness) | Thin sheets, precision pipes, wires |

| Hot-rolled Profiles | Hot rolling followed by cooling | Thicker, high strength, rough surface, cost-effective | Thick plates, I-beams, channels, angle steel |

| Extruded Profiles | Mold extrusion | Complex cross-sections (e.g., shaped tubes), suitable for custom small batches | Hollow square tubes, custom profiles, decorative trims |

| Welded Profiles | Formed by welding sheets | Low cost, high production efficiency, but welded seams may reduce strength | Welded pipes, square tubes, structural frames |

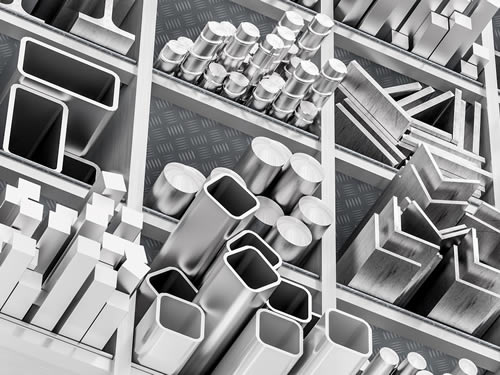

II. Classification by Cross-Sectional Shape

| Category | Shape Characteristics | Common Specifications | Typical Applications |

|---|

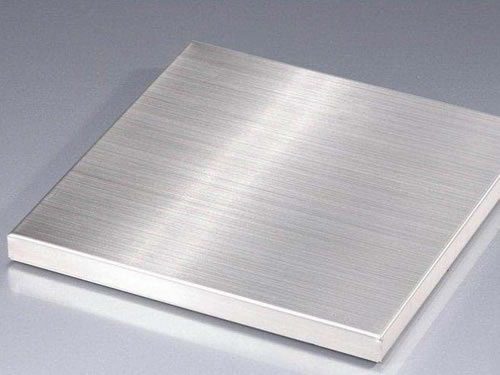

| Plates | Flat thin/thick sheets | Thickness: 0.1 mm–50 mm | Building facades, kitchenware, industrial containers |

| Tubes/Pipes | Hollow circular/square/rectangular | Diameter: 1 mm–2000 mm | Fluid transport, structural support, railings |

| Bars | Solid round/hexagonal/flat | Diameter: 3 mm–300 mm | Shafts, bolts, tool handles |

| Structural Profiles | Specific shapes (angle steel, channels, etc.) | Angle steel side length: 20 mm–200 mm | Building frames, shelves, machinery bases |

| Wires | Thin round or flat strands | Diameter: 0.1 mm–6 mm | Springs, welding wires, mesh |

| Strips | Narrow, thin coiled bands | Width: 10 mm–500 mm; Thickness: 0.05 mm–3 mm | Electronic components, battery plates, precision parts |

III. Classification by Material Grade

| Grade | Core Properties | Suitable Applications |

|---|

| 201 | High manganese, low corrosion resistance, economical | Dry environments (indoor railings, furniture) |

| 304 | 18% chromium, 8% nickel, general corrosion resistance | Food equipment, outdoor structures, chemical pipelines |

| 316 | 2–3% molybdenum, resistant to seawater and acids | Marine engineering, medical devices, high-corrosion environments |

| 430 | Ferritic stainless steel, oxidation-resistant but low toughness | Appliance panels, automotive exhaust systems |

| Duplex Steel | Austenitic + ferritic structure, high strength, chloride-resistant | Oil pipelines, desalination plants, bridge structures |

| 904L | High-alloy super austenitic, acid-resistant | Chemical reactors, nuclear equipment |

IV. Classification by Surface Treatment

| Treatment | Process Description | Effect & Applications |

|---|

| 2B Finish | Cold-rolled + annealed + pickled | Matte surface for industrial equipment, structural parts |

| BA Finish | Bright annealing | High reflectivity for electronics, decorative materials |

| Brushed | Mechanical sanding | Anti-fingerprint, scratch-resistant (elevator doors, appliance panels) |

| Mirror Polishing | Multi-step polishing | High-end decoration (hotels, luxury displays) |

| Sandblasted | High-speed sand impact | Uniform matte texture (building exteriors) |

| PVD Coating | Vacuum ion plating | Colored finishes (rose gold, black titanium) |

V. Classification by Application Scenarios

Architectural Structural Profiles

Load-bearing profiles: I-beams, H-beams (stadiums, bridges)

Decorative profiles: Mirror-finished tubes, brushed sheets (shopping mall facades, stair railings)

Industrial Equipment Profiles

Pressure-resistant profiles: Seamless thick-walled pipes (boilers, high-pressure vessels)

Corrosion-resistant profiles: 316L round bars (chemical pumps, reactor parts)

Consumer Goods Profiles

Food-grade profiles: 304 thin sheets (utensils, countertops)

Lightweight profiles: Thin-walled square tubes (furniture, display racks)

VI. Key Selection Parameters

Mechanical Properties: Tensile strength (≥520 MPa for high strength), elongation (affects formability)

Corrosion Resistance: Match material to environment (e.g., 316 for coastal areas, 304 for general use)

Dimensional Tolerance: Precision equipment requires cold-rolled profiles (±0.05 mm), structural uses allow flexibility

Processing Compatibility: Avoid stress corrosion in welded profiles; protect mirror surfaces during handling

Accurate classification and selection enhance project efficiency and material longevity. From industrial machinery to daily essentials, stainless steel profiles underpin modern engineering and design.